Everything you need to know about free scan and inventory order inventory counts in Texada WorkFlow.

Quick Reference

- Inventory counts are one of Texada WorkFlow’s key features. They can help you identify missing or misplaced items as well as ensure that your physical inventory matches your digital records.

- Inventory counts are a collaborative effort between an inventory manager (using the WorkFlow web application) and a warehouse operator (using WorkFlow for iOS or Android).

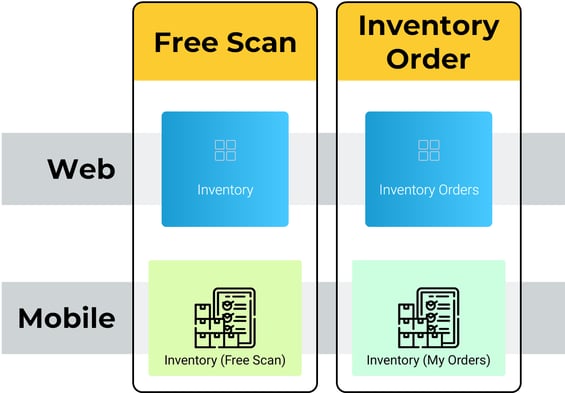

- There are two types of inventory count in Texada WorkFlow: Free Scans and Inventory Orders. The differences between them are summarized in the following table:

|

Free Scan |

Inventory Order |

|

Initiated in the Texada WorkFlow mobile application. Warehouse operators can initiate a new count at any time. |

Initiated in the Texada WorkFlow web application. Inventory managers can create a new batch, add equipment to it, then assign it to a warehouse operator for completion. |

|

No prescribed list of assets to be scanned. The warehouse operator can add new items to the count as they are scanned. |

Consists of a specific list of assets to be scanned. New items can only be added to the list by the inventory manager. |

|

Offers a physical-first approach to inventory management, as lists are filled out dynamically as items are scanned. |

Offers a digital-first approach to inventory management, as physical items are matched against a prescribed list. |

Introduction

One of WorkFlow’s key features is the ability to perform inventory counts. Inventory counts can help you identify missing or misplaced items as well as ensure that your physical inventory matches your digital records.

In Texada WorkFlow, an inventory count is a collaborative effort between an inventory manager (using the WorkFlow web application) and a warehouse operator (using WorkFlow for iOS or Android). Depending on the type of inventory count, the manager may initiate and assign the inventory count, or simply review it once it is complete. The warehouse operator is responsible for completing the count itself. Using the camera on their mobile device, they can move through your physical inventory and scan asset barcodes as they go.

The following article will tell you everything you need to know about initiating and completing inventory counts in Texada WorkFlow.

Free Scan vs. Inventory Order

There are two types of inventory count in Texada WorkFlow: Free Scans and Inventory Orders. The primary difference between the two is that free scan inventory counts are initiated by the warehouse operator and do not include a prescriptive list of items to count: rather, the operator adds new items to the count as they are scanned. By contrast, inventory orders are always created in the Texada WorkFlow web application and the list of items to be scanned is fixed.

In other words, free scans offer a physical-first approach to inventory management, where the process of counting serves as a way to discover what is currently in inventory at a given time. Inventory orders, meanwhile, offer a digital-first approach to inventory management, where the digital record serves as a gold standard against which the physical inventory is checked.

Both free scans and inventory orders have a web and a mobile component. The Processes used to complete each type of count are indicated in the following image:

For more information on these Processes, see the following help articles:

Free Scan

Inventory Order

Free Scan

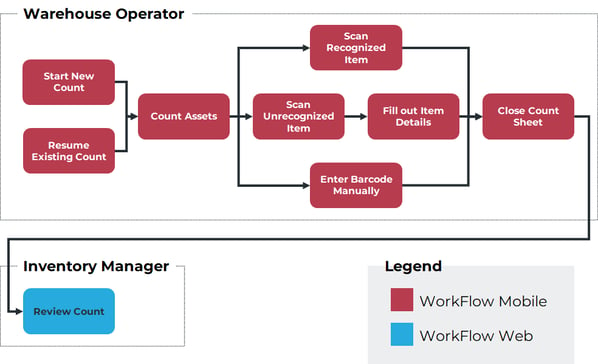

The workflow for a free scan inventory count. Click to view the full-size image.

The workflow for a free scan inventory count. Click to view the full-size image.

The workflow for a free scan inventory count begins in the Texada WorkFlow mobile app. Using the Inventory (Free Scan) Process, the warehouse operator can either start a new inventory count or resume an existing one.

To add items to the count, the operator can either scan an item’s barcode or enter its barcode number directly. If the operator scans or enters the barcode of an unrecognized item (one that is not present in inventory), they will have the option of filling out its details and including it in the count.

Once the operator has finished counting, they can either exit the Process, thus leaving the count open, or choose to close it, at which point they can submit a closing comment. Both open and closed counts can be reviewed via the Inventory Process in the Texada WorkFlow web application.

Inventory Order

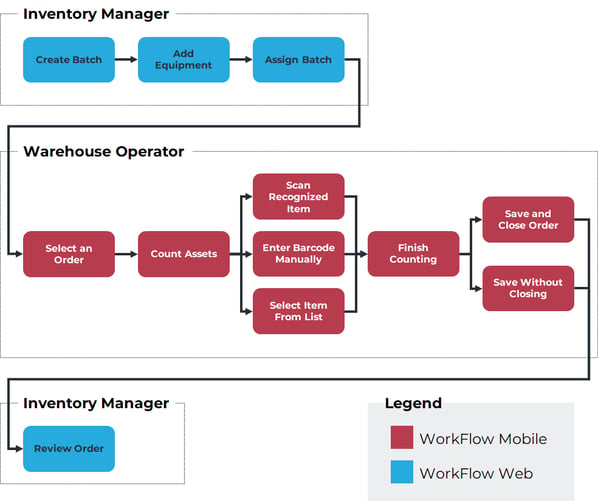

The workflow for an inventory order. Click to view the full-size image.

The workflow for an inventory order. Click to view the full-size image.

The workflow for an inventory order begins in the Texada WorkFlow web application. Using the Inventory Orders Process, the inventory manager creates a new batch of assets and builds out a list of equipment to scan. They then assign the order to a warehouse operator for completion.

Using the Inventory (My Orders) Process, the warehouse operator completes the inventory count. They can scan items using their device’s camera, enter barcodes manually, or simply mark items as counted as they move through the list. Unlike when completing a free scan, the warehouse operator is not able to add new items to the list; the inventory manager, however, is able to modify the list at any time using the Inventory Orders process.

Once the operator has finished counting, they can opt to leave the inventory order open and resume it later, or finalize and close it. Both open and closed orders can be reviewed via the Inventory Orders process.